The tooling range

Ultra compact clinching tool kits

RIVCLINCH® tooling range

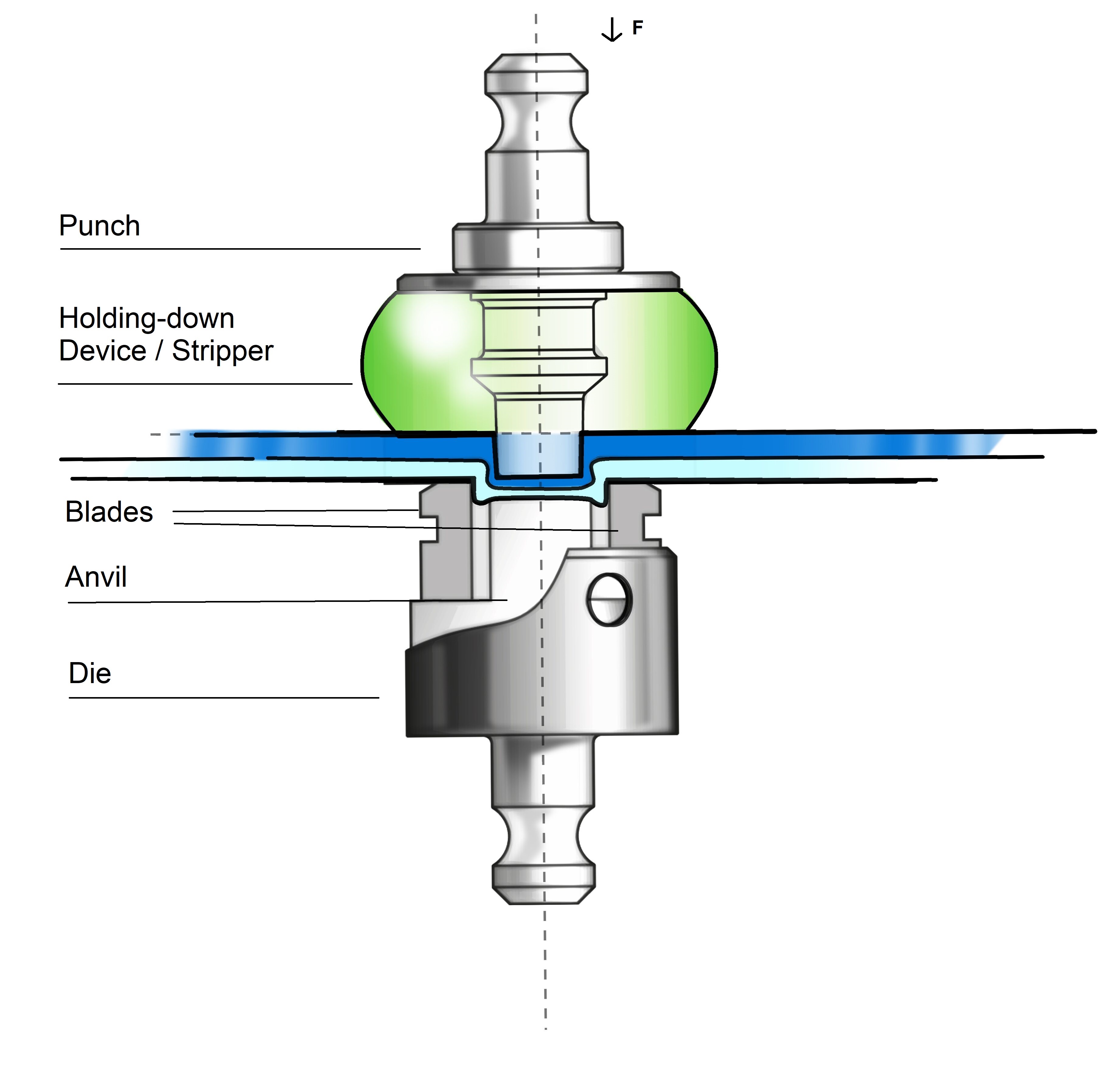

The central component of the clinching joining system is the tooling.

The punch, die and its integral anvil form the clinching tool kit.

A wide offer of standard tooling diameters are available to produce either round or rectangular clinch joints.

Criteria for the choice of tooling:

1) Material (mild steel, stainless steel, aluminium, copper etc.)

2) Material thickness

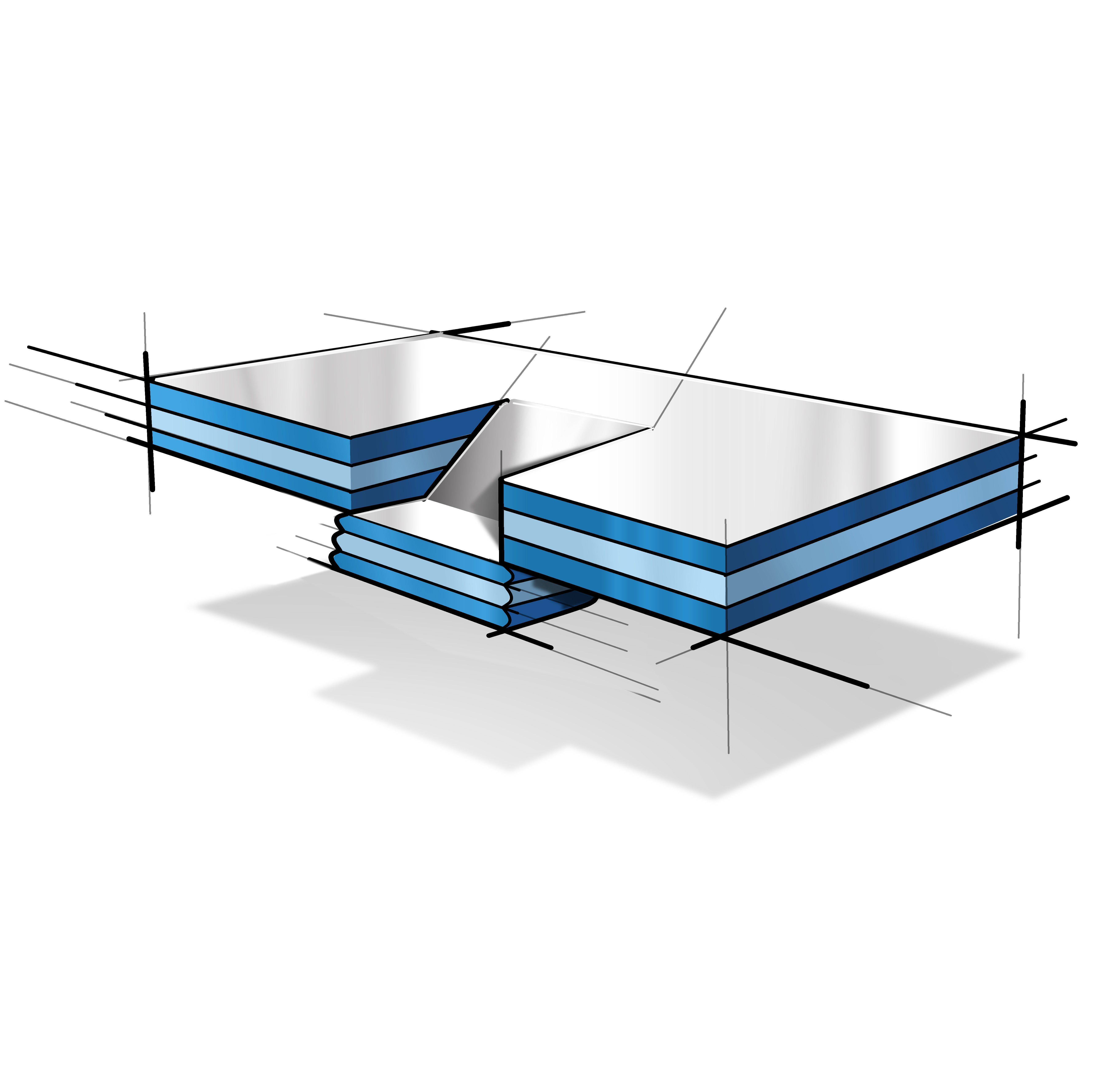

3) Sheet combination (number of layers and order between punch and die)

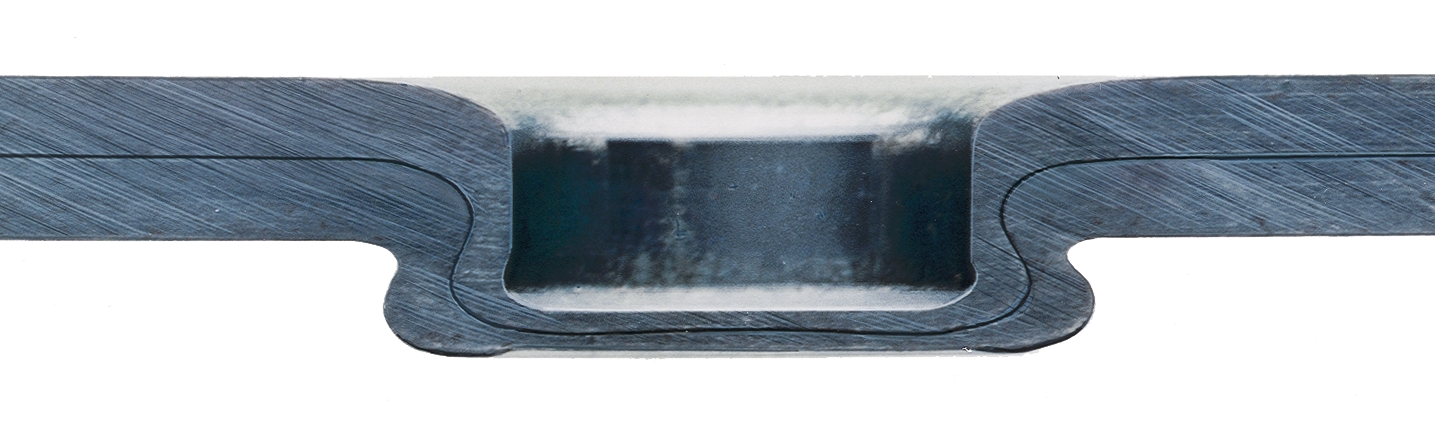

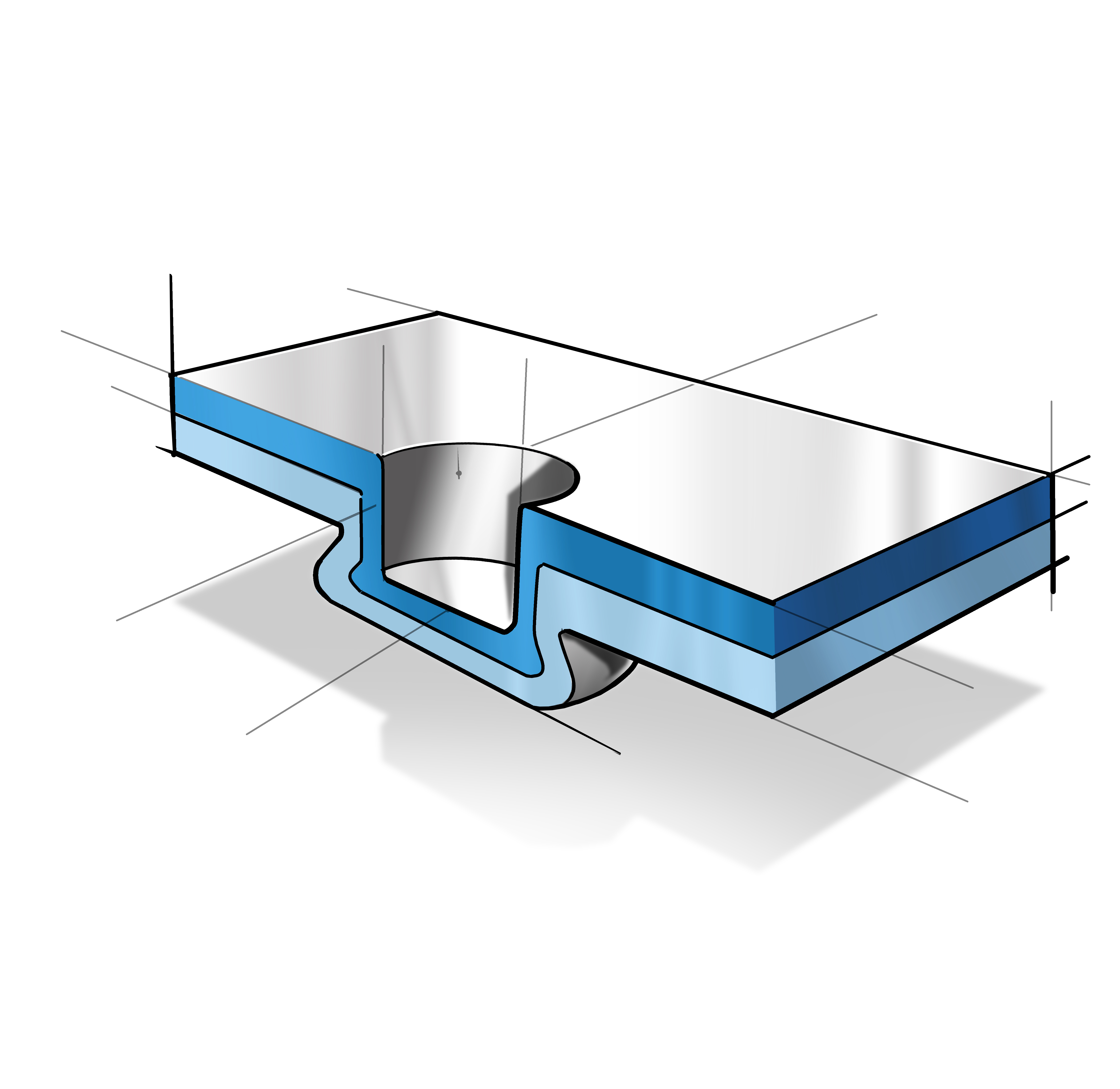

Depending on the clinching tool selected, the resulting joint will be either round or rectangular:

Round joint SR (Spot Round)

|

Rectangular joint ST (Spot Rectangular) |

A large offer of clinching tools has been designed to fit every application :