Pneumatic standalone clinching machine

Cost effective, multi-purpose clinching machine

This safe, fast and multipurpose standalone machine insures easy positioning of the tool at the clinch joint location prior to clinching.

Without re-opening the full stroke at each clinch operation you will be able to make series of joints at full speed.

As an option, the work cycle can be automatically controlled by an Optimized Cycle Controller (OCC) insuring that the clinch joint is completed in the shortest possible cycle time.

This machine is equipped with our PASS system for optimal security and efficiency.

A fast multi-purpose machine :

- Large opening up to 60 mm

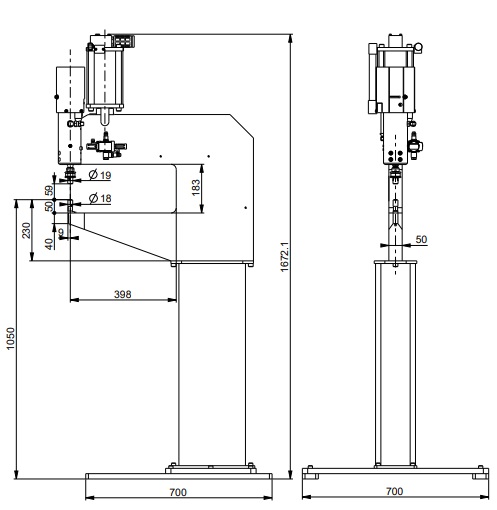

- Depth opening of 400 mm (More on demand)

- Foot pedal operation: your hands are completely free

- Safety approach system

A wide range of patented RIVCLINCH® tool are available for this machine, allowing to join thin sheet as well as thick material up to more than 4 mm total thickness, in most combination of materials such as mild steel, Aluminium and Copper.

| Weight | 230 kg - 470 lbs |

| Working air pressure | 6 bar - 87 psi |

| Cycle time | 1.0 - 1.2 sec |

| Joining force | 50 kN - 112 klb |

| Work stroke | 8 mm - 0.31'' |

| Total opening | 60 mm - 2.05'' |

| Depth | 400 mm - 15.7'' |

| Max. total sheet thickness, Mild steel | 4.5 mm - 0.17'' |

| Max. total sheet thickness, Aluminum | 5 mm - 0.20'' |

| Max. total sheet thickness, Stainless steel | 3 mm - 0.12'' |

One of our RC 4006 P50 PASS clinching machine features is the Passive Approach Stroke System (PASS).

It consists of a separate foot pedal for the approach stroke, which is run at low force and allow a large access to work pieces up to 60 mm high.

Once the piston is down, the punch gap is below 8 mm, and the second foot pedal can be activated for the clinching operation at full force.

In addition to the safety aspect, the PASS facilitates the positioning of the tool at the clinch joint location prior to clinching, and allows to make series of joints at full speed without re-opening the full stroke at each clinch operation.

A wide range of patented RIVCLINCH® tool are available for this machine, allowing to joint thin sheet as well as thick material up to more than 4 mm total thickness, in most combination of materials such as mild steel, Aluminium and Copper

The tool kits must be selected from the original RIVCLINCH® series SR 603 (round) or ST 502 (rectangular) based on the application.

Other types of tool kits, for specific applications: Ventilation ducting, Filters, Stainless steel, Aluminum, and also other dimensions of tool kits are available.

The machine is delivered complete ready to use including piedestral, air preparation unit, double foot pedal.

Only simple connection to 6 bars compressed air is required.

As an option, the work cycle can be automatically controlled by an Optimized Cycle Controller (OCC) insuring that the clinch joint is completed in the shortest possible cycle time.

Due to its long and thin lower jaw, this unit is perfect to join metal parts for a large number of applications in the Building sector, HVAC, Appliances, Vehicles, Furniture, Electric, Roofing and many other sectors.